STAAD Advanced Concrete Design RCDC 2023 (23.00.02.43) Win x64

- ПРОГРАММЫ

- 25-07-2023, 00:05

- 228

- 0

- TUTBB

Free Download STAAD Advanced Concrete Design RCDC 2023 (23.00.02.43) | 1.7 Gb

Bentley Systems Incorporated is pleased to announce the availability ofSTAAD Advanced Concrete Design RCDC 2023 (23.00.02.43). This is a minor release with the following new features and design capabilities.

Product:STAAD Advanced Concrete Design RCDC

Version:2023 (23.00.02.043)

Supported Architectures:x64

Website Home Page :www.bentley.com

Languages Supported:english

System Requirements:Windows *

Size:1.7 Gb

RCDC (SACD) V23.0.2 release notes

- Beam Ductile detailing Enhancement - All design codes - The area of reinforcement provided is used in all cases to satisfy all ductile member-related detailing requirements in the beam module.

- Column effective length factor Enhancements in redesign tools - All design codes - The option to recompute the effective length factor at various stages of column design and redesign is now available

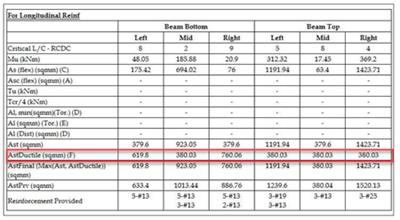

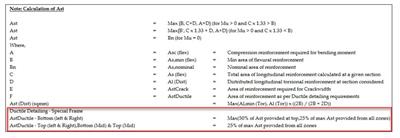

BeamBeam Ductile detailing Enhancement - All design code

Various design codes provide the ductile detailing requirement for the top and bottom reinforcement of the beam. Example: As per the ACI code, the positive moment strength at the joint face shall be at least one-half the negative moment strength provided at that face of the joint. Here, the Moment strength is to be calculated as per the provided reinforcement in the beam. The moment strength cannot be calculated as per the required reinforcement as provided reinforcement can be much more than the required reinforcement

RCDC is performing ductile detailing for the top and bottom reinforcement of the beam as per code requirements. The area of reinforcement provided at the section is used for the ductile detailing. However, due to some limitations in a few cases, instead of using the provided area of reinforcement, the area of reinforcement required was used to satisfy the ductile detailing requirements. It is now made consistent in all cases and the area of reinforcement provided is used.

The design calculation report is also enhanced by adding a new row to give more clarity about the area of reinforcement required as per ductility criteria. Corresponding code criteria are also added in the note section for easy reference.

Close

ColumnColumn effective length factor Enhancements in auto and redesign tools

In the column design, an effective length factor is calculated which is required to perform the slenderness check. As per the type of frame (Sway and Non-sway), section size, and material properties of the column and beam, the effective length factor is calculated for the column.

RCDC provides options to change the material grades and member sizes at various stages of the design and redesign. RCDC now recomputing the effective length factor if the user has changed the column size or material properties at various design and redesign stages.

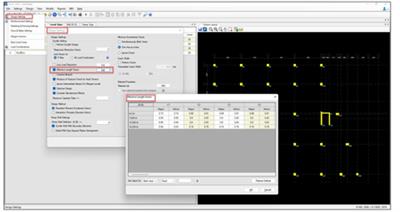

Recompute effective length factor prior to the Auto design stage: Users compute the effective length factor from the design setting screen.

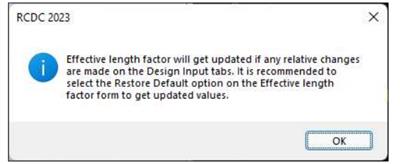

Now, if the user changes the column size, and concrete grade at the input stage, RCDC will show a below warning message to the user.

Close

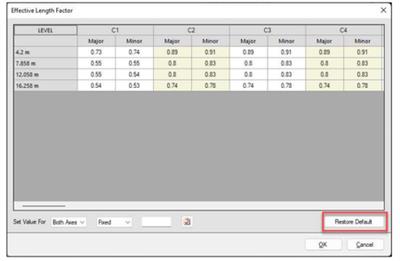

It is expected that the user will update the effective length factor after modifying data like column shape, column size, and concrete grade on the input screen. The warning message will be displayed once to the user. If the user does multiple changes on the input screen, it is the user's responsibility to recompute the effective length factor after updating all the changes. The re-computations can be done by selecting restoring default values on the screen of the effective length factor of design settings.

It is suggested that the user should do all the changes first and then compute the effective length factor. If the user does the changes on the input screen first and then moves to the design setting to calculate the effective length factor, RCDC will take the latest data to compute the effective length factor. At this stage, no warning message will be displayed to the user.

Recompute effective length factor post to the auto design stage:

If the user changes the column shape or width of the section, depth of the section, or concrete grade, the user can recompute the effective length factor using the 'recompute effective length factor' button.

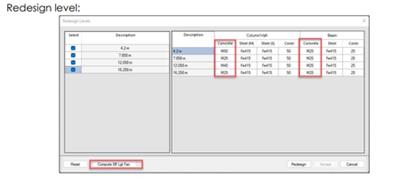

If the user does changes in any of the marked values, RCDC will activate the 'compute effective length factor' button to recompute the effective length factor.

If the user does changes in any of the marked values, RCDC will activate the 'compute effective length factor' button to recompute the effective length factor.

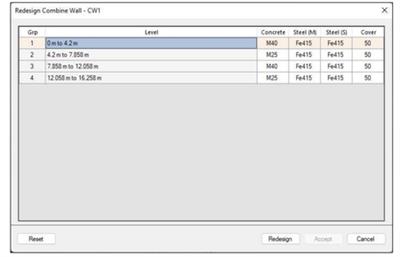

If the user does change the concrete grade, RCDC will activate the 'recompute effective length factor' button to recompute the effective length factor. Redesign Combined wall:

Close

The effective length factor for the walls that are part of the combined wall is considered 0.1 as default. Thus, recompute button is not provided here.

GeneralDefects Resolved

Following is the list of Defects resolved in this release.

ADO ID - 675415 - issue in calculating the unsupported length if structural steel beams are supported on the RC column.

The unsupported length of the column is calculated as per the floor-to-floor height deducting the depth of the beam resting on it. The beam resting on the column can be RC or structural steel. The unsupported length of the column is calculated along both directions of the column.

Issue:

When the structural steel beam is supported on the RC column, the incorrect unsupported length was calculated for that column. The wrong structural steel beam depth was considered for the calculation of the unsupported length.

Solution:

Actual structural steel beam depth is now considered to calculate the unsupported length of the column.

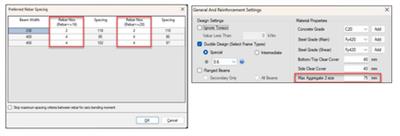

ADO ID - 1042993 - Beam-Preferred rebar spacing validation is provided if the Maximum aggregate size is changed.

The preferred rebar spacing in the beam is dependent on the beam size, rebar diameter, and maximum aggregate 2 (Metal) size given by the user.

Issue:

The preferred rebar spacing is calculated using the maximum aggregate 2 sizes available in the general and reinforcement settings screen. The input for maximum aggregate 2 sizes is available prior to the calculation of preferred rebar spacing. If the maximum aggregate size is changed after calculating the preferred rebar spacing, the rebar numbers were not updated on the rebar spacing screen. It was causing issues with the redesign tools. The number of rebars should be recalculated as per the updated maximum aggregate 2 size.

Solution:

When the user changes the maximum aggregate 2 sizes, the preferred spacing is updated on the backend and updated the rebar numbers are used in the further auto and redesign steps. The below snaps show the rebar numbers are updated after changing the Max. Aggregate 2 sizes to 75mm as compared to size of 25mm in the previous snap.

ADO ID - 1083595 - Tank structures - issue in reading STAAD file if a slab of the tank is modeled with an opening in it.

Presently RCDC reads the opening in the tank wall, however, for the design and detailing opening is not considered. The standard reinforcement details around openings are provided in the detailed drawings.

Issue:

If the user has modeled the tank slab with an opening in it, RCDC was unable to read the tank model. There was no issue reading STAAD file if the opening is in the tank wall.

Solution:

The reading tank structure is now handled if there are slabs with openings in them.

ADO ID - 1166877 - Issue in updating higher rebar diameter for shear design

Generally, the shear force is higher at the ends and lesser at the mid-zones of the beam. Similarly shear due to sway action (Sway left and sway right action for ductile beams) gives a higher shear force at ends and less shear force at midzones.

Issue:

In a few cases specifically at mid-zone where area of shear reinforcement required due to sway action is higher than the end zones, RCDC was not trying the rebar diameter to a higher diameter to satisfy the shear detailing requirements. It was taking the diameter of end zones for the mid zone and if it was not satisfying, it was showing detailing failure at mid zone.

Solution:

At the mid zone, if the shear rebar diameter required is higher than the end zones, RCDC is now increasing the diameter to satisfy the area of shear reinforcement required.

ADO ID - 1206007 - Load combination -An error message was missing if any load combinations don't consist of a single dead load case in it.

Generally, each load combination must be created with at least one dead load case. If load cases are present in the load list but it is not used in any of the load combinations, RCDC is used to show an error of "at least one dead load case should be present in the load combinations".

Issue:

When the user imports the load combination definition directly from analysis and there is no dead load case present in any of the load combinations, RCDC was not showing an error in the latest released version. When load combinations are created through standard templates available in RCDC, it takes care of creating load combinations with at-least one dead load case specified in the code requirement.

Solution:

If there is no dead load case present in any of the load combinations, RCDC is now showing an error of missing dead load cases in the load combination.

ADO ID - 1207034 - ACI code - slenderness check presentation issue in cases

where there is only axial force in column (no Bending Moments) In the ACI codes column design, the effect of the end bending moment includes in the calculation of the permissible slenderness check value. The direction of the end bending moment plays an important role to identify whether the column is bent in single or double curvature based on which the permissible slenderness value is calculated.

Issue:

In a case where the column is experiencing only axial forces without any bending moment, there was an issue in the presentation of permissible slenderness value in the design calculation report. There was no issue with the design of the column as correct final bending moments are calculated based on the slenderness checks.

Solution:

The design calculation report presentation is updated with all possible cases and correct permissible slenderness values are presented.

ADO ID - 1236141 - ACI code - Beam design - Inconsistent result of auto design and redesign if the beam is designed with axial force and biaxial moments

RCDC allows to design of the beams with axial force and biaxial bending moments. Users can select this option of beam design from the design settings screen.

Issue:

In one of the cases, the beam with axial force and biaxial moments shown passed in the auto design. but it was showing it as failed on the redesigned screen using the same design settings as auto design. The issue occurred as different rebar layers were used in the auto and redesign step.

Solution:

The auto design and redesign steps are made consistent now. If any beam failed in the auto design will now show a similar type of failure on the redesigned screen.

RCDCis the industry leading concrete detailed engineering software. It is a powerful software that delivers a completely seamlessly integrated process linking analysis to design & detailing, drawings, estimation and reporting. RCDC is used across a wide spectrum of industry including high rises, residential, commercial, industrial and infrastructure projects.

RCDC General Features Video

Bentley Systems, Incorporated.is the global leader dedicated to providing architects, engineers, constructors, and owner-operators with comprehensive architecture and engineering software solutions for sustaining infrastructure. Founded in 1984, Bentley has nearly 3,000 colleagues in more than 45 countries, $500 million in annual revenues, and, since 2001, has invested more than $1 billion in research, development, and acquisitions.

Rapidgator-->Click Link PeepLink Below Here Contains Rapidgator

http://peeplink.in/de9170fed008

Uploadgig

j9zsx.SETUP.rar

NitroFlare

j9zsx.SETUP.rar

Links are Interchangeable - No Password - Single Extraction