Cavity Casting Aluminum & Mold Design With SolidWorks

Cavity Casting Aluminum & Mold Design With Solidworks

Published 6/2023

MP4 | Video: h264, 1280x720 | Audio: AAC, 44.1 KHz

Language: English

| Size: 3.83 GB[/center]

| Duration: 6h 8m

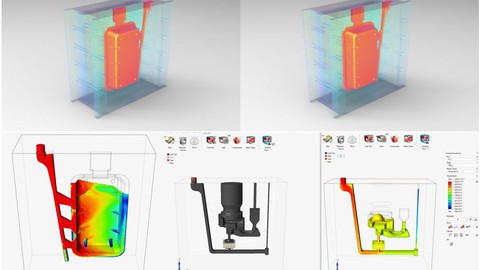

Mold design with software Solidworks & Cavity casting aluminium with software Inspire Cast

What you'll learn

Students will learn how to modify the piece to perform in reality.

How to do draft analysis and part wall thickness analysis.

How to make design changes from idea to realization to production.

I will teach the students how to create a mold for casting aluminum in the cavity, they will also learn when and how to use sand core.

We will apply some methods that you have not seen before in the design and casting of aluminum in the cavity, also the problems that are found in the production

You will have basic and professional knowledge to work in this type of industry because in this course you will learn aluminum flow and analysis with software.

After completing the course you are able to complete the projects for which this course is dedicated.

Requirements

You must have solidworks software for design, and if you want to do metal flow simulation you must have Inspire Cast software

Description

In this course, students will learn how to complete a project from start to finish, including:1. Product analysis, can the cavity casting product be realized?2. Basic knowledge in aluminum casting, where we will realize several different projects3. Mold design with Solidworks software using several different methods.4. The simulation and analysis of aluminum appears to be done in the Inspire Cast software, you will have basic knowledge of this Inspire Cast software moduleAfter completing this course, students will be able to carry out various projects in this type of industry and mold crime in the plastic industry, they will also learn a lot from this course to design for their personal needs.Students will have a different concept to realize a project after completing this course.Në këtë kurs do të realizojmë projekte që nuk mund të realizohen vetëm me bërthamë, do të realizojmë me bërthamë rëre kur është e nevojshme në pjesën, gjithashtu do të përgatisim kallëpin e zallit për projektin që duhet të realizohet.Industria e derdhjes së aluminit është e ndërlikuar, nëse nuk kuptoni bazat është shumë e vështirë të krijosh një kallëp, në këtë industri është më e rëndësishme të ndërtohet si duhet kallëpi, parametrat e tjerë gjatë procesit mund të rregullohen.

Overview

Section 1: How to create the cavity in different ways

Lecture 1 Shortcut keyboard in solidworks

Lecture 2 Making a simple part to continue how to make a cavity casting mold

Lecture 3 How to make a Mold with Surface.

Lecture 4 How to make mold tools with solidworks command

Lecture 5 How to make a mold with Indent command.

Lecture 6 How to make cavity in solidworks assembly.

Lecture 7 How to make a Mold with combine.

Section 2: How to modify a part and prepare it for designing a mold

Lecture 8 Thickness analysis

Lecture 9 Draft Analysis and change of slope angle.

Lecture 10 Preparation of the part to proceed with the mold

Section 3: Design & cavity casting process and simulation

Lecture 11 The rules and basic knowledge of the cavity casting process

Lecture 12 The design of the filling system, the gate and the feeder Video-1

Lecture 13 The design of the filling system, the gate and the feeder Video-2

Lecture 14 Basic information for aluminum simulation for cavity casting

Lecture 15 First simulation with the Inspire Cast software

Lecture 16 The second and third simulation with the Inspire Cast software

Lecture 17 Filling Results

Lecture 18 Solidification Results

Section 4: Creating the mold with Solidworks software

Lecture 19 Creating the mold with the Solidworks software

Lecture 20 Placement of injection pins as well as shrinking of the aluminum

Lecture 21 Creating pins that turn the plate back, linear and injection plate.

Lecture 22 Completion of this Mold project

Lecture 23 Mold guide pins and opening hole for set up mold

Section 5: The file of the first project

Lecture 24 Project 1

Section 6: Project 2

Lecture 25 Basic knowledge of the part before starting the project

Lecture 26 Shrinking the aluminum and planning how the aluminum will flow.

Lecture 27 The design of the filling system, the gate and the feeder

Lecture 28 Comparison of the aluminum flow results of the project with minor changes

Lecture 29 Creating the mold with the Solidworks software pr-2

Lecture 30 Pins that turn the plate back, linear, injection pins and injection plate V-1

Lecture 31 Pins that turn the plate back, linear, injection pins and injection plate V-2

Lecture 32 Checking that everything is properly with the mold and motion for this product

Section 7: The file of the second project

Lecture 33 Project 2

Section 8: Project 3

Lecture 34 Information about the third project

Lecture 35 The design of the filling system, the gate and the feeder and analysis

Lecture 36 Creating the mold for sand with the Solidworks software

Lecture 37 Creating the mold with the Solidworks software

Section 9: The file of the third project

Lecture 38 Project 3

This course is for students who want to learn: Aluminum cavity casting, mold design, design modification, design analysis and project implementation.

https://fikper.com/1gwxJOoJwo/Udemy_Cavity_casting_aluminum_Mold_design_with_solidworks_2023-6.part1.rar.html

https://fikper.com/g2TMXGiyOc/Udemy_Cavity_casting_aluminum_Mold_design_with_solidworks_2023-6.part2.rar.html

https://fikper.com/hFEBhPqJkX/Udemy_Cavity_casting_aluminum_Mold_design_with_solidworks_2023-6.part3.rar.html

https://rapidgator.net/file/13cee6d50aa0123f3fcbf895a12164b3/Udemy_Cavity_casting_aluminum_Mold_design_with_solidworks_2023-6.part1.rar

https://rapidgator.net/file/dc2b9455f06a646192d218e667d464a5/Udemy_Cavity_casting_aluminum_Mold_design_with_solidworks_2023-6.part2.rar

https://rapidgator.net/file/19d62b63a6fc36cb5930d560ef5268ec/Udemy_Cavity_casting_aluminum_Mold_design_with_solidworks_2023-6.part3.rar

https://katfile.com/2c7gsq3iyi9h/Udemy_Cavity_casting_aluminum_Mold_design_with_solidworks_2023-6.part1.rar

https://katfile.com/iu28u0un383j/Udemy_Cavity_casting_aluminum_Mold_design_with_solidworks_2023-6.part2.rar

https://katfile.com/c4o29ychh4zd/Udemy_Cavity_casting_aluminum_Mold_design_with_solidworks_2023-6.part3.rar

Free search engine download: Udemy Cavity casting aluminum Mold design with solidworks 2023-6